Gauges & Fixtures

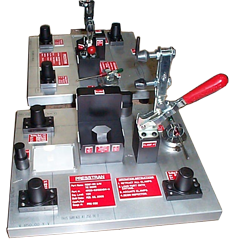

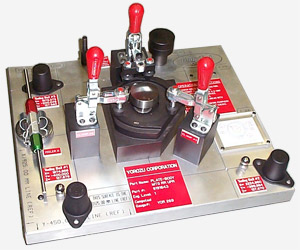

ComPuTool Gauge & Fixture specializes in manual operator-controlled gauges and fixtures. Our gauges are used to inspect metal stamped parts, machined parts, plastic parts, and part assemblies.

Types of Fixtures

- CMM positioning / holding fixtures

- SPC fixtures

- Attribute checking fixtures

- Environmental inspection gauges

- Assembly checking fixtures

- Cooling fixtures

- Welding fixtures & jigs

We will build to your general or specific gauge and fixture specifications.

Gauge & Fixture Durability

Our gauges and fixtures are designed to be durable and built for long life. Our gauges and fixtures feature robust clamps and moving components to withstand the rigors of plant floor use. All critical fixture components are doweled and keyed. We harden all guides and contact surfaces.

Better Quality Gauges

ComPuTool is making better gauges in terms of quality and maintainability. We have been incorporating more standard gauge components into our gauge builds thus reducing the variability associated with custom components.  We use non-marking clamps so all inspected parts can be returned to production. We rely on fixture base suppliers for standard bases whenever possible. Our aluminum and steel fixture bases have a solid base plate and fabricated supports. The single piece fabrication has a high structural rigidity at lower weight.

We use non-marking clamps so all inspected parts can be returned to production. We rely on fixture base suppliers for standard bases whenever possible. Our aluminum and steel fixture bases have a solid base plate and fabricated supports. The single piece fabrication has a high structural rigidity at lower weight.

During gauge maintenance, standard components are readily available and easily replaced. As a side benefit, by using standard components, ComPuTool is able to efficiently build to time-critical schedules.

Gauge & Fixture Documentation

Gauges and fixtures will ship complete with requisite documentation. Dimensional inspections and gauge study reports will be supplied to your requirements. Operating procedures and gauge maintenance documentation are included with all fixtures. All of our gauges and fixtures can be supplied with ISO-IEC 17025 certification.